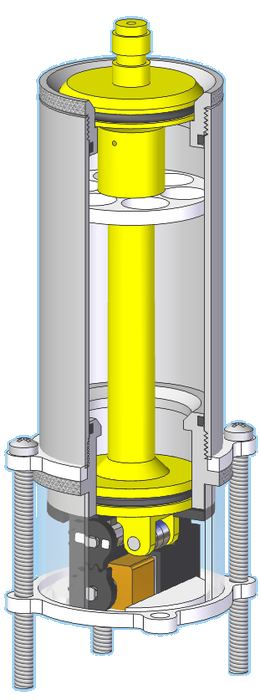

Preparation:

Device is filled with pressurized CO2 or high pressure compressed air through the

paint ball style quick disconnect fitting on top which is passed through a check

valve into the main gas chamber.

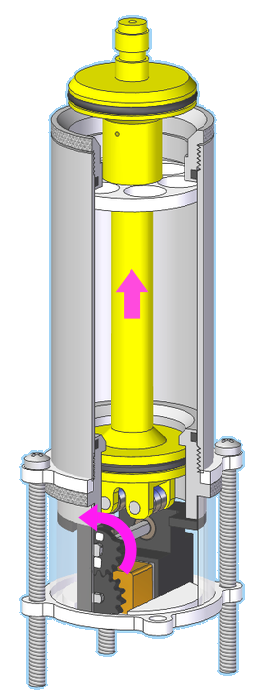

Activation:

A voltage(1.5-12v) is passed to the geared motor in the base of the device which

(through some simple gearing) turns the main latch shaft. As this shaft is rotated

90deg, the latch will disengage and will allow the main load shaft & pistons to move

freely (axially). A piston is fixed to each end of the main load shaft to seal each

end of the gas chamber; however, the top piston is of a subtly larger diameter than

the bottom piston thereby creating a subtle force differential from the gas pressure.

Due to this force differential, the top piston has subtly more pull on the main shaft

than the base piston thereby pulling the complete main shaft upwards which beyond

a certain point will open the device’s gas contents for rapid release.

The dual piston arrangement allows the bulk of the load to be transferred to the

main load shaft (inside the gas chamber) thereby exposing minimal load to the actual

latch shaft mechanism to minimise dynamic stresses and thereby maximise mechanical

reliability.

A high throughput opening allows for instant gas release to maximise the power

from the available energy & in turn maximise deployment reliability.